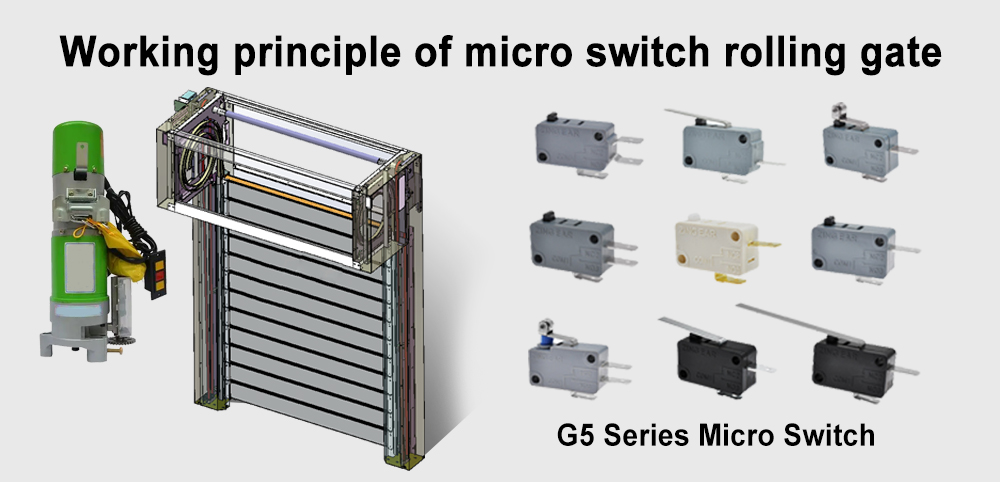

The working principle of the rolling gate G5 series micro switch

When using rolling gates, you generally have to pay attention to the issues of fixation, position and welding. These problems will directly affect the use and operation of the switchgear, thus affecting the life of the switchgear. Let me introduce these problems to you. The fixing method of the G5 series micro switch of the rolling gate: screw fixing, two fixing methods are adopted, one is three-point fixing, and the other is two-point fixing. This method is more suitable for the situation that there are many buttons on the rolling shutter door. It can make a certain distance between the switch and the buttons to avoid wear and tear due to the close distance between the switch and the buttons.

The main application of G5 series micro switch:

It is a novel and reliable automatic control device for remote control opening of electric rolling gates and electric rolling doors. The design idea of this product is to realize the remote control opening function of the electric rolling gate through a micro-contact. Since the action of this product is continuous action, it is required that the selected micro switch must have the characteristics of fast action and long life.

The design principle of rolling gate lock:

When rolling the gate lock, the action principle and operation method must be determined according to the structural characteristics of the rolling gate lock. It must be safe, reliable, and easy to operate. Among them, the control of the rolling gate is an important aspect, so the micro switch on the rolling gate is in the Rolling shutters play an important role;

A micro switch is a common control device, usually installed at the switch of a motor or other electrical equipment. The main function is to convert the operation of closing and opening into a simple position control, and it can be adjusted by an external circuit; the rolling gate lock must have good sealing performance and be able to withstand the tension and pressure during normal use; the rolling gate lock should have Good rainproof, dustproof performance, and has a long service life.

How does the rolling gate control the switch:

Rolling gate, a kind of building material, is also called automatic door. It is a door that is opened and closed by one or more types of scrolls, which are rotated and pushed by the transmission mechanism. Rolling gates are divided into manual rolling gates and electric rolling gates;

Generally, rolling gates can be divided into three categories: translational type: it means that the rolling shutter door achieves the purpose of closing the door through manual expansion and contraction, and is generally suitable for garages, warehouses and other places. The size of the driving current is used to achieve the purpose of controlling the lifting of the door curtain. It is generally suitable for occasions with fire protection requirements. When a fire breaks out, the door curtain can automatically rise to prevent the fire from spreading. And telescopic (telescopic door): It refers to a way for the rolling door to control the lifting of the door curtain through the remote control and the electric control lock.

The working principle of the micro switch:

Inside the micro switch there is a normally open contact and a normally closed contact. When the two contacts make contact, the trigger coil is energized and the release contact closes. If neither contact is opened or closed, the microswitch is not functioning properly. When the two contacts are opened or closed, the electromagnet is compressed and releases pressure.

Micro switches are often used in motor control and power equipment control. Micro switches are mainly composed of buttons, contacts and springs. The button is located on the main contact to make or break the circuit; the contact is located between the two switches to make or break the circuit; the spring is located between the switch and the contact to provide tension. When the motor turns, the spring is compressed, creating a pressure; when the motor stops, the spring is stretched, releasing the pressure. When the contactor coil is energized, the relay’s coil is energized and generates current; when the contactor coil is de-energized, the relay’s coil is de-energized and releases pressure. There is no voltage difference between the normally open and normally closed points of the relay. In this state, the pressure can be released by the spring to prevent the circuit from shorting; and in this state, the pressure can be released by the spring to prevent the circuit from shorting.