The article not only shows you the micro switch in vacuum cleaner but also tells where it is, as well as the cleaner working operating principle, and so on.

Vacuum Cleaner Operating Principle

The working principle of the vacuum cleaner is to rotate the motor at high speed so that the dust enters the dust filter bag in the dust box through the ground brush, connecting pipe, handle, hose, and main suction pipe. Then, the filtered air enters the motor through a filter layer, a protective barrier to prevent the broken dust bag from being sucked into the motor. The air entering the motor flows out through the motor. Due to the carbon brush’s continuous wear during the motor’s operation, another filter is added before it flows out of the vacuum cleaner.

The finer the filter material, the cleaner the air can be filtered, but the poorer the air permeability, which affects the air volume sucked by the motor and reduces the efficiency of the vacuum cleaner. But for users, comfort and cleanliness is the main thing.

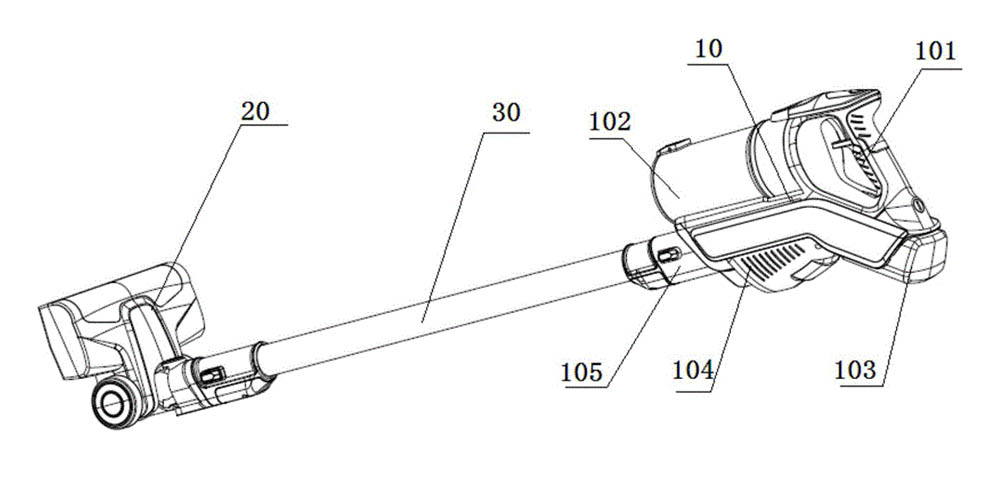

The Parts of Vacuum Cleaner

The Electric Motor

Without the electrical motor, your vacuum would certainly struggle with a serious loss of power. It is a necessary aspect of modern-day models. The majority of motors will certainly operate with upwards of 1800 watts. The lower-end units will certainly hover around 1600 watts.

The Angled Fan Blades

Plane propeller blades inspire the air blades in your conventional model. Those tilted blades supervise the developing suction power and maintaining air relocating continuously with a standard vacuum cleaner.

The Porous Dust Bag

Debris from carpeting doesn’t stand an opportunity against vacuum cleaner filters. Permeable dirt bags are an attribute located in a bagged vacuum and are precisely where their name originates from. They remove loose dust, dirt bits, as well as other air particles that are unfavorable.

The Intake Port

The intake port provides a stable stream of air so that the vacuum cleaner can maintain suction power. The speed at which air sucks right into the unit is directly symmetrical to the rate of the fans.

The Exhaust Port

The exhaust port gives an opposite yet corresponding feature to the intake port. This is the spot where the stream of air is permitted to recede.

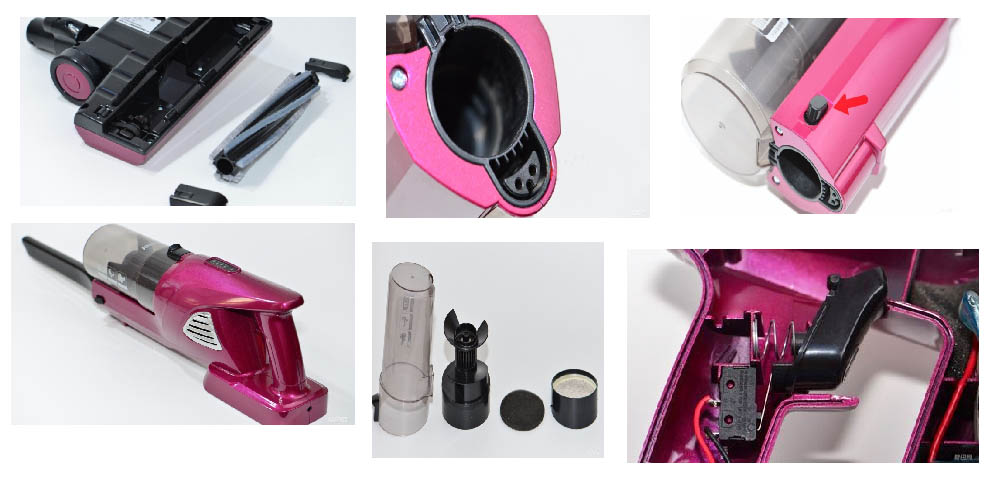

Micro Switch in Vacuum Cleaner

Where a micro switch is installed in the vacuum cleaner

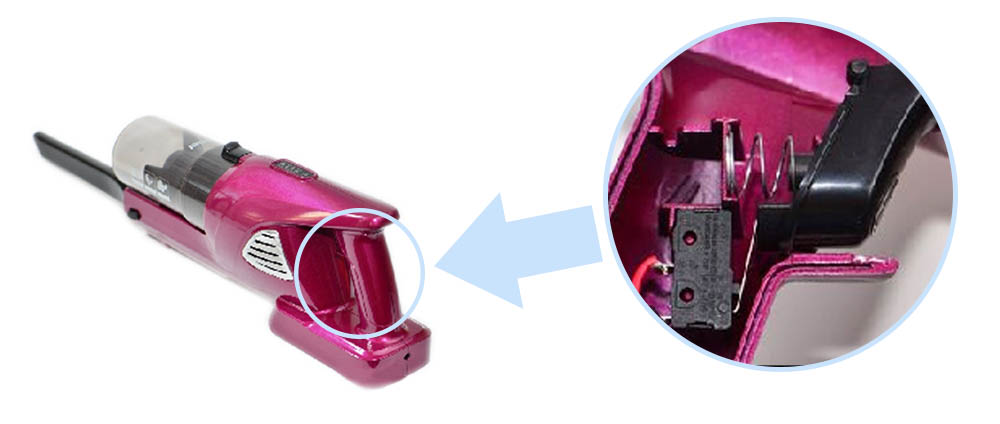

Generally, the micro switch will be located in the handle’s body or the power head so the user can easily control it. There is not only a micro switch for these control parts. It also needs a cover to increase the pressure feeling. Just like this picture.

It can control the electric motor on and off so the vacuum cleaner can start working or stop.

If you are now handling a new design project, you are welcome to contact us to select a suitable model because different project needs different micro switches.

The requirement for a micro switch

So, this micro switch requires functions like switch loading, circuit, working temperature, operating force, connecting terminal, and certification.

Firstly, the micro switch must meet the requirement of motor rating. For example, the motor rating is 1A 220VAC, and its instantaneous current is 24A(just for example). Using a 3(3)A 125/250VAC switch will not be enough for it because of the instantaneous current. The 3(3) 125/250VAC means the instantaneous current is 3*6=18A. Although 3A can cover 1A, 18A can’t cover 24A. So, choose a 3(4)A 125/250VAC rating micro switch. As well as the DC motor.

Secondly, the switch circuit function. Usually, the snap action switch has SPDT, SPST-NC, SPST-NO, DPDT, DPST NO, and DPST NC. We here only discuss the single pole type. In our experience, this cleaner button needs the SPST NO function, which means the vacuum cleaner will start working when you press it. So, please make no mistake when choosing the microswitch circuit.

Thirdly, the operating force need not be too light because the user needs to know the press feeling too. Generally, most of the switches’ working temperatures can cover.

Finally, the safety certification. Because the cleaner belongs to the household appliances, America needs the UL(cUL), Europe needs the ENEC, some Asian countries need the CQC, and so on. So, the safety certification is also important for you. As well as, the safety certification can ensure the switch quality.

All in all, we can provide the micro switch in vacuum cleaner, welcome to contact us for more details.

Related Micro Switch in Cleaner

- Micro ON/OFF Switch Normally Closed NC T125 5A Zing Ear CompanyGrandyeAdmin2021-06-18T05:43:05+00:00

- Micro Momentary Switch 5A 30VDC 25T125 SPDT Solder Terminal TypesGrandyeAdmin2022-10-20T03:50:23+00:00

- G605-150S00A Solder Terminal Miniature Pin Plunger Micro SwitchGrandyeAdmin2021-02-20T05:41:37+00:00