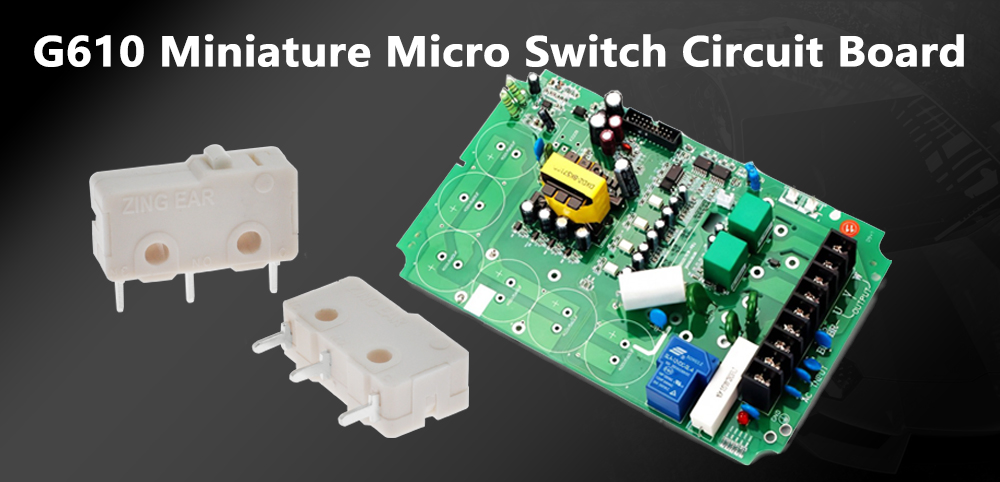

A G610 Series miniature micro switch circuit board refers to the electronic circuitry associated with a miniature micro switch. While the microswitch itself is a mechanical component responsible for the physical actuation, the circuit board is the electronic part that handles the electrical signals generated when the microswitch is activated.

Here’s a basic overview of how a G610 Series miniature microswitch circuit board might work:

G610 Series Miniature micro switch Integration: The miniature micro switch is mechanically integrated into the circuit board. The lever or button of the micro switch might protrude from the board, allowing it to be actuated by an external force.

1. Contacts: Inside the G610 Series microswitch, there are electrical contacts that come into contact or separate when the microswitch is actuated. This closing or opening of contacts generates an electrical signal.

2. Wiring: The contacts of the microswitch are connected to traces on the circuit board. These traces carry the electrical signal generated by the switch to other components on the board.

3. Components: Depending on the application, the circuit board might have various components connected to the G610 Series miniature microswitch. These components could include resistors, capacitors, diodes, and even microcontrollers or other integrated circuits.

4. Signal Processing: The circuit board might process the signal from the micro switch in some way. For instance, it could debounce the signal to eliminate any noise caused by the mechanical bouncing of the switch contacts.

Output: The processed signal from the miniature micro switch circuit board can then be used for various purposes. It could trigger an action in a device, send a signal to a microcontroller or computer, or be part of a larger electronic system.

The specific design and components of a G610 Series miniature microswitch circuit board can vary widely depending on the intended application. For instance, a circuit board in a computer mouse might have a microcontroller that interprets the signals from multiple microswitches to track mouse movement and button clicks. On the other hand, a circuit board in an industrial machine might use microswitches to trigger safety shutdowns.

The structure design of the circuit board

The design of a circuit board involves several key aspects to ensure its functionality, reliability, and manufacturability. Here’s an overview of the structure and design considerations for a typical circuit board:

1. Layers

Circuit boards are typically constructed with multiple layers of material. The most common type is a multi-layer board, which consists of several layers of copper traces and insulating material sandwiched together. The number of layers depends on the complexity of the circuit and the components used.

2. Substrates

The base material of the circuit board is often made of fiberglass-reinforced epoxy resin, commonly known as FR-4. This material provides both mechanical strength and electrical insulation. Other substrates might be used for specialized applications, such as flexible circuits or high-frequency boards.

3. Copper Traces

Conductive pathways on the circuit board are made of copper traces. These traces connect components and circuit elements, allowing the flow of electrical current. Copper traces can be etched onto the substrate using various methods.

4. Components

Circuit boards have various electronic components mounted on them. These can include microchips (integrated circuits), resistors, capacitors, diodes, connectors, and more. Components are soldered onto the board through holes (through-hole components) or on the surface (surface-mount components).

5. Pads and Vias

Pads are areas on the circuit board where components are soldered. Vias are holes that connect different layers of the board, allowing traces to pass through. Vias can be plated (conductive) or non-plated (insulated).

6. Silkscreen

The silkscreen layer is used for marking components, component values, reference designators, logos, and other information. It’s printed on the board in a contrasting color to the board material.

7. Solder Mask

The solder mask is a layer that covers most of the board’s surface, leaving only the solder pads exposed. It prevents solder bridges and provides protection against environmental factors like dust and moisture.

8. Routing and Layout

The arrangement of components, traces, and vias is critical for proper signal integrity and to prevent issues like interference or crosstalk. Layout tools help designers optimize the routing and placement of components.

9. Power Planes

The inner layers of a multi-layer board might be dedicated to power and ground planes. These large areas of copper provide a low-resistance path for current to flow and help manage noise and heat.

10. Design Software

Specialized software, such as Electronic Design Automation (EDA) tools, is used for creating and editing circuit board designs. These tools offer features for schematic capture, component libraries, layout design, and design rule checking.

11. Design Rules

Design rules are guidelines set by the manufacturer or industry standards that ensure the board can be manufactured reliably. They dictate factors like trace width, spacing, hole sizes, and more.

12. Testing Points

Test points are designated areas on the board where test probes can be connected to verify the functionality of the circuit during manufacturing and quality control.

The structure and design of a circuit board can become quite complex, especially for more intricate designs. Professionals with expertise in electrical engineering, PCB design, and manufacturing work together to create circuit boards that meet the intended functionality, reliability, and manufacturing requirements.

A G610 Series miniature microswitch, often simply referred to as a micro switch, is a type of electrical switch that is actuated by a very small physical force. These switches are commonly used in a wide range of applications where precise and reliable switching is required. They consist of a housing, a lever or button, and contacts that open or close based on the position of the lever or button.

Here are some key features and applications of miniature microswitches:

1. Features:

Small Size: Miniature microswitches are designed to be compact, making them suitable for applications where space is limited.

Precise Actuation: They are sensitive to even minor changes in force or position, ensuring accurate switching.

Long Lifespan: Microswitches are known for their durability and long operational lifespan, often rated for millions of cycles.

Quick Response Time: Due to their mechanical nature, microswitches can provide rapid response times when compared to other types of switches.

2. Applications:

Keyboards: Many mechanical keyboards use microswitches under each key to register keypresses.

Automotive: Microswitches can be found in various automotive components, such as door locks, window controls, and seat adjustments.

Appliances: They’re used in appliances like microwave ovens, refrigerators, and washing machines for door interlocks and control functions.

Industrial Equipment: Microswitches are used in industrial machinery to detect position, limit movement, and provide safety shutdowns.

Gaming Controllers: Microswitches are used in gaming controllers for buttons and triggers due to their precise actuation.

Medical Devices: In medical equipment, microswitches can be found in devices such as infusion pumps and diagnostic equipment.

Security Systems: They’re used in security systems for detecting door/window openings, motion, and other actions.

When choosing a micro switch for a specific application, factors to consider include the required actuation force, electrical specifications (voltage, current), mounting options, and environmental conditions (temperature, moisture, etc.).