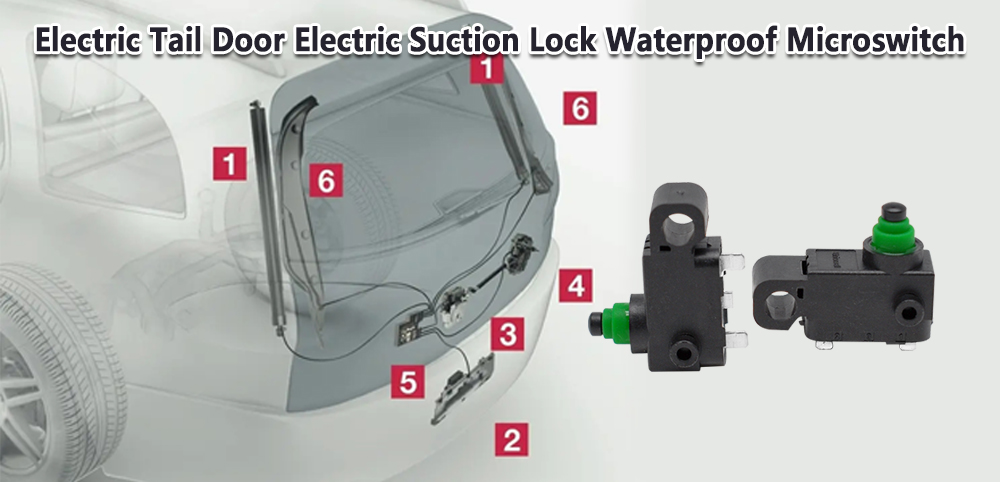

Working principle of tailgate electric suction lock waterproof microswitch

The working principle of the tailgate electric suction lock waterproof micro switch involves electromagnetic suction, micro switch and waterproof design. Electric tailgate latch usually includes an electromagnetic catcher, which is responsible for locking the tailgate securely when needed. This electromagnetic clutch is usually attracted or released by the electromagnetic field generated when electric current passes through the coil.

A micro switch is a small switch that switches quickly when exposed to external pressure or movement. In the tailgate electric suction lock, the micro switch is usually associated with the position and status of the tailgate.

Since the tailgate electric suction lock faces possible intrusion from rainwater or other liquids, its design usually includes waterproof measures. This can include sealing rubber gaskets, waterproof coatings or other materials to ensure that water does not get inside the locks and micro switches during inclement weather or car washes.

When the tailgate is closed, the electromagnetic catcher is energized and generates a magnetic field to attract and lock the tailgate. In this state, the micro switch may be triggered, indicating that the tailgate has been completely closed. When the car owner triggers unlocking through the remote control or the car button, the electromagnetic suction device usually loses power, weakening or eliminating the attraction. The tailgate thus becomes openable. During this process, the micro switch may be triggered again, indicating that the tailgate is open. The waterproof design ensures that water will not penetrate into the key components of the electric suction lock and micro switch at any time, especially on rainy days or during car washes.

This design ensures the reliability of the tailgate electric suction lock, allowing it to function normally in all weather conditions and preventing damage from moisture or other external elements.

How can a waterproof micro switch improve the performance of the tailgate electric suction lock?

The application of waterproof micro switch in the tailgate electric suction lock can significantly improve the performance. The combination of waterproof design strategies can effectively improve the water resistance of the micro switch in wet or humid environments, ensuring its use in the tailgate electric suction lock system. works reliably. Waterproof design plays a key role in improving equipment reliability, extending life and reducing maintenance costs.

Waterproof micro switches generally comply with automotive industry standards and requirements, ensuring their safety and reliability in automotive applications. The application of waterproof micro switches can improve the performance of the electric tailgate lock so that it can still work stably and reliably under various harsh conditions, thus improving the overall quality and user experience of the vehicle.

1. Waterproof design

The waterproof micro switch adopts special sealing design and materials to effectively prevent water, moisture, rain or other liquids from entering the inside of the switch. This helps prevent corrosion and oxidation of switch components, thereby improving switch reliability.

Waterproof design is an engineering design method that aims to prevent liquids from entering the interior of electronic, electrical, mechanical or other equipment to ensure stable operation of the equipment in wet or humid environments. For the application of waterproof micro switches in tailgate electric suction locks, waterproof design becomes particularly important. Use materials with good sealing properties, such as rubber, silicone or other waterproof sealing materials, to wrap the key components of the micro switch in a waterproof layer. This helps prevent moisture from seeping into the interior of the switch.

Use rubber sealing rings at the connection points or key interfaces of micro switches to prevent moisture from penetrating through the connection gaps. This seal is usually elastic and maintains a seal as the switch moves. Covering the external surface of the microswitch with a waterproof glue coating provides additional protection. This glue coating is usually durable and has good weather resistance. IP protection rating is a measure of a device’s resistance to intrusion by solid and liquid objects. Ensure that the microswitch has the appropriate IP protection rating to meet the environment in which the tailgate electric suction lock system will be used.

Design the structure of the microswitch so that its external components fit as closely as possible to reduce potential penetration paths. This helps reduce the possibility of moisture getting inside the switch. Design drainage channels on the bottom or sides of the microswitch so that any moisture that may enter can drain quickly without being trapped in critical areas. Conduct regular water tightness tests on waterproof micro switches and ensure that they comply with relevant protection standards and certification requirements.

2. Resistant to harsh environments

The tailgate electric suction lock is located at the rear of the vehicle and is easily affected by bad weather and environment. Waterproof micro switches can operate stably in humid, rainy or dusty conditions, reducing failures caused by the external environment.

When designing electronic, mechanical or other equipment to operate in harsh environments, a number of factors need to be considered to ensure that the equipment will operate reliably and have a long life. Here are some key considerations. Water resistance is an important factor in ensuring that your device will work in wet, rainy or liquid environments. Use sealing materials, sealant coatings, rubber seals and a good IP rating to prevent moisture penetration.

In dusty environments, equipment should be dustproof. Sealing design and appropriate filtration system can effectively prevent dust and particulate matter from entering the equipment. If equipment is exposed to corrosive gases, chemicals, or other corrosive substances, corrosion-resistant materials are required to ensure that the equipment does not corrode and degrade performance.

Equipment needs to be able to operate properly in environments with high or low temperatures. Proper thermal design, insulation materials and appropriate temperature control systems can help cope with extreme temperature conditions. In harsh industrial environments or moving vehicles, equipment needs to have good resistance to vibration and vibration to prevent failures caused by vibration.

3. Enhanced durability

Waterproof micro switches are usually made of durable materials, making them more resistant to frequent switching operations and the impact of the external environment. This improves the durability of the switch and reduces wear and tear due to prolonged use.

4. Reliable signaling

Waterproof micro switches are designed to reliably transmit signals even in wet or harsh conditions. This is crucial for the accurate operation of the tailgate electric suction lock, especially when the rear of the vehicle needs to be kept safe and stable.

5. Avoid short circuits and malfunctions

The waterproof design not only provides waterproofing but also helps prevent short circuits and other electrical malfunctions. This ensures that the tailgate electric suction lock system can still work properly in wet or humid environments and avoids performance problems caused by circuit failures.

Electric tailgate electric suction lock

Gone are the days of manually opening and closing your vehicle’s tailgate. With the power tailgate, convenience is at your fingertips. This feature allows you to easily open and close the tailgate with just the push of a button. Whether you have your hands full with groceries or need to load bulky items into your vehicle, a power tailgate eliminates the hassle of manual operation.

The electric suction lock is an important part of the electric tailgate system. It ensures the tailgate locks securely in place when closed, giving you peace of mind and added security. Unlike traditional mechanical locks, electric suction locks use an electric mechanism to form a vacuum seal to keep the tailgate closed firmly. This eliminates the risk of the tailgate opening accidentally while driving, even over rough terrain.

Waterproof micro switch

In order to further enhance the reliability and durability of the electric tailgate and electric suction lock, a waterproof micro switch is added to the system. This micro switch is designed to withstand water, ensuring it will continue to operate flawlessly even in rainy or wet conditions. The microswitch’s waterproof feature prevents any potential damage from water intrusion, extending the life of your power tailgate system.

Benefits of electric tailgate with electric suction lock and waterproof micro switch

-

Convenience of electric tailgate

The electric tailgate opens and closes easily, making loading and unloading items more convenient. No more struggling with a heavy tailgate or fumbling for keys.

The electric tailgate saves car owners the trouble of manually opening or closing the vehicle’s trunk. With a simple push of a button, remote or other control, owners can accomplish this quickly and easily without using additional force.

The power tailgate offers convenience when shopping, carrying luggage or other items, as owners can easily open the trunk while their hands are occupied. This is especially useful for those carrying large or heavy items.

Many power tailgate systems come with a remote control that allows the owner to operate the tailgate from a certain distance. This remote control function makes it easy to control the opening and closing of the tailgate even if the arm is not long enough, the line of sight is blocked, or under other circumstances.

-

Security and reverse functions

The electric suction lock ensures that the tailgate remains securely closed, minimizing the risk of accidents caused by the tailgate suddenly opening while driving. This is especially important when driving on uneven or bumpy roads.

Some advanced electric tailgate systems have intelligent functions, such as programmable height and opening and closing speed, electric tailgate memory function, etc. These functions can be customized according to user needs to provide a more personalized experience.

Electric tailgates are usually equipped with sensors and reverse functions to ensure that objects or people are not caught during the closing process. This increases safety of use, especially when small children or other pedestrians are around.

3. Durability

Waterproof micro switch protects the power tailgate system from water damage, increasing its lifespan and reliability. This feature is particularly beneficial for people who live in areas with frequent rainfall or for off-road enthusiasts who encounter wet conditions.

-

Enhance security

Electric suction locks provide an extra layer of security against potential theft or unauthorized vehicle entry. The vacuum seal created by the electric suction lock ensures that the tailgate cannot be forced open easily.

-

User friendly

The electric tailgate system is designed with user convenience in mind. Simple button operation and reliable locking mechanism make it easy for anyone to use, regardless of age or physical condition.

The electric tailgate with electric suction lock and waterproof micro switch is a significant advancement in automotive technology. It offers convenience, safety, durability, enhanced security and user-friendliness. Whether you’re a busy parent, an outdoor enthusiast, or someone who simply values convenience, this innovative feature is sure to enhance your vehicle ownership experience. Embrace the future of automotive technology with an electric tailgate system.